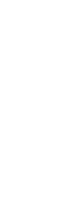

When the snap-fit groove on the cap work, the two grooves overlap and the capsule is sealed completely, that prevent the stuffing from leaking.

The cone cut on the capsule body make it easy to stuff the capsule and avoid locking failure.

The pre-lock notches inosculate with the grooves on the capsule body entirely, that ensure the cap and capsule body could not separate during transportation and stuffing process.

The two air vents on the capsule body keep the pressure inside same as that outside all the time, no matter stuffed or not, that protect the capsule from damage in stocking and using, and meet the requirement for high speed filling machines well.

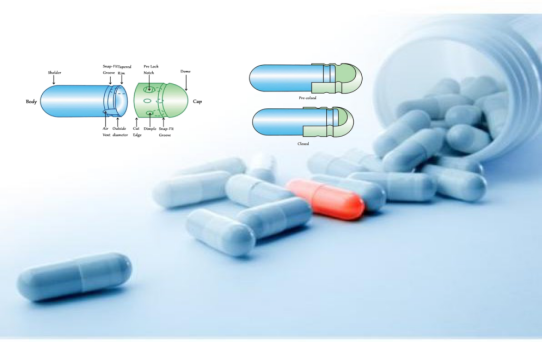

We can make special designs according to customers' color requirements. Healsee has a fully automatic intelligent blending system, using pure natural pigments to prepare empty capsules of various colors to ensure uniform, stable and non-differential colors.

Healsee capsules have a complete range of models, including 5-000 capsules, to meet the different size requirements of customers.

000#

00#el

00#

0#el

0#

1#

2#

3#

4#

5#

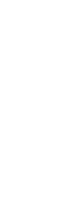

The capsules are printed using advanced printing equipment and nationally certified pharmaceutical-grade ink on Their surface.

Depending on customer requirements, we offer axial, circumferential, directional, or dual-color printing, ensuring an aesthetically pleasing appearance with clear, legible text and patterns. This enhances your product's visual appeal, boosts competitiveness, and strengthens brand recognition.

Elevate Your Brand with Secure, High-Impact Differentiation

Secure. Distinctive. Ready to Impress.

Comprehensive Sizing & Customization for Your Unique Needs

Precision. Flexibility. Trusted Expertise.